Achieve Superior Material Splitting Up With Advanced Dust Screens for Recycling Plants

Go into sophisticated dust screens, an innovation that holds the promise of revolutionizing the method waste is refined. These cutting edge displays are developed to successfully separate dust and other impurities from recyclable products, making certain a greater quality output. In this conversation, we will discover the solutions to these inquiries and delve into the variables to think about when choosing dirt displays, as well as their execution and maintenance.

The Value of Advanced Dust Screens

The importance of innovative dust displays in reusing plants can not be overstated as they play a critical duty in dividing and removing pollutants from recyclable products. These displays are particularly created to efficiently and properly eliminate dirt, particles, and other undesirable products from the recycling process, guaranteeing that high-grade and just tidy recyclables are refined further.

One of the primary reasons innovative dust displays are important is that they aid improve the overall high quality of recyclable products. By removing pollutants such as dust, rocks, and other non-recyclable products, the screens ensure that the final recycled products are of greater pureness and meet the called for sector criteria. This not just enhances the value of the recycled materials but additionally raises their bankability.

Additionally, progressed dust displays aid to prevent damages to reusing equipment. Contaminants like rocks or steel items can cause substantial damages to machinery such as conveyors, crushers, and shredders, causing expensive repairs and downtime. By properly separating these contaminants at the onset of the reusing process, dust screens aid to extend the lifespan of the devices and reduce upkeep expenses.

Along with enhancing material high quality and protecting tools, advanced dust displays likewise add to a much safer working setting - dirt screens for sale. By eliminating sharp things, dangerous products, or potentially dangerous substances, these displays lower the danger of injuries or accidents to employees, ensuring a much safer office for everyone included

Just How Advanced Dirt Screens Work

Advanced dust displays in recycling plants function by making use of specialized systems to different and remove contaminants from recyclable products, making certain that top quality and just tidy products continue through the recycling procedure. These displays are designed to deal with big quantities of combined waste and effectively remove unwanted compounds, such as dust, debris, and smaller particles, from the recyclable materials.

The initial step in the procedure entails the feeding of mixed waste materials onto the dirt display. The screen is equipped with a series of openings or openings that enable smaller bits to go through while preserving larger and much more important products. As the waste products move along the display, a mix of gravitational forces and mechanical resonances aids to divide the impurities from the recyclables.

To take full advantage of effectiveness, advanced dirt screens use numerous modern technologies, such as oscillating or shaking displays, to improve the separation process (dirt screens for sale). These displays can be fine-tuned to attain the preferred separation size, ensuring that just the cleanest and most beneficial products continue through the reusing procedure

Furthermore, some advanced dust displays use air jets or suction systems to even more enhance the splitting up process. These systems blow or vacuum cleaner away lighter pollutants, such as paper or plastic film, leaving behind the larger and a lot more important recyclable materials.

Key Advantages of Utilizing Advanced Dirt Screens

Making use of advanced dirt displays in recycling plants provides countless advantages in terms of effectiveness, performance, and overall high quality of the recycling process. These innovative screens are developed to divide dust, debris, and other unwanted products from the recyclable products, resulting in a purer end item.

Another advantage is the boosted performance of the recycling process. Advanced dirt displays are made to accurately and efficiently separate recyclable products from impurities, ensuring a higher quality output. This assists to fulfill rigorous recycling standards and allows for the production of cleaner and purer materials that can be utilized in different markets.

Along with performance and performance, making use of innovative dust displays additionally adds to the total quality of the recycling procedure. By removing dust and particles, the displays aid to decrease the threat of contamination, making certain that the recycled products are of a greater criterion. This not just enhances the value and marketability of the recycled materials but also advertises sustainability by reducing the demand for virgin raw products.

Variables to Think About When Selecting Dirt Screens

When picking dirt screens for reusing plants, it is necessary to take into consideration various aspects to ensure ideal efficiency and efficiency. One of the initial aspects to think about is the size of the screen. The dimension of the dirt display will certainly figure out the dimension of the fragments that can go through, so it is vital to select a display dimension that is appropriate investigate this site for the specific materials being refined.

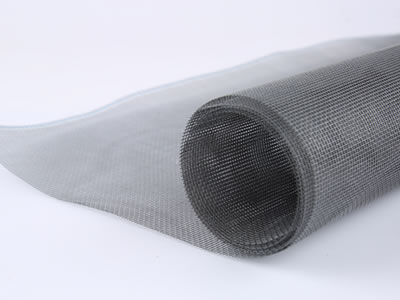

An additional essential aspect to think about is the material of the display. Different materials have various levels of resilience and resistance to tear and use. It is important to pick a screen product that can stand up to the extreme conditions of the recycling plant and preserve its performance over time.

Furthermore, the style and setup of the dust screen must be taken right into account. The display must be made to take full advantage of the separation of different materials and avoid blocking or obstructions. The spacing between the wires or perforations on the screen should be carefully chosen to attain the wanted splitting up effectiveness.

Moreover, the upkeep demands of the dirt screen need to additionally be taken into consideration. Displays that are simple to clean and maintain will certainly assist to reduce downtime and guarantee continuous operation of the recycling plant.

Execution and Upkeep of Dirt Screens

To successfully execute and keep dirt displays in reusing plants, cautious factor to consider should be offered to their installation and recurring upkeep. Appropriate installment is important to ensure the screens operate optimally and supply superior material splitting up.

Normal upkeep this post is essential to keep dirt displays in optimum problem and optimize their performance. This consists of regular inspections to identify any type of signs of wear or damage, such as tears or holes in the screens.

Cleaning the screens frequently is likewise crucial to avoid blockages and ensure continuous operation. This can be done utilizing different methods such as air or water blasts, depending on the type of screen and the degree of dust build-up. When cleaning up the screens to stay clear of creating any type of damage., it is Check Out Your URL important to follow manufacturer standards and suggestions.

Final Thought

In conclusion, the use of sophisticated dust displays in reusing plants is essential for accomplishing remarkable product splitting up. These displays properly remove dirt and other contaminants, guaranteeing the production of top notch recycled products. The vital advantages of making use of innovative dust displays consist of boosted effectiveness, enhanced product high quality, and lowered upkeep prices. When picking dust displays, aspects such as screen size and material should be considered. Correct execution and normal upkeep of these screens are vital for optimal performance.

These sophisticated screens are made to divide dirt, particles, and other unwanted products from the recyclable materials, resulting in a purer end item. Advanced dust screens are made to precisely and efficiently different recyclable materials from contaminants, making certain a higher quality end item. The size of the dust screen will certainly identify the size of the bits that can pass through, so it is essential to choose a display dimension that is suitable for the specific products being processed.

In final thought, the use of sophisticated dirt displays in reusing plants is vital for achieving superior material splitting up. When choosing dust screens, variables such as screen dimension and material should be thought about.